Case Study Knauf

The Case

Efficient Modernization of Knauf Plants through 3D Laser Scanning

In today’s industry, the precise and efficient modernization of production facilities is crucial for a company’s long-term success. A remarkable example of this is the modernization of nine Knauf plants across seven different countries, where 3D laser scanning was used as a key technology.

The Challenge

Modernizing Older Plants with Minimal Operational Disruptions

Knauf, a global leader in building materials manufacturing, faced the task of modernizing several of its older production facilities. The challenge was to carry out these modernizations in a way that would minimize disruptions to ongoing operations. Traditional surveying methods would have resulted in longer downtimes and significantly disrupted the production flow.

The Solution

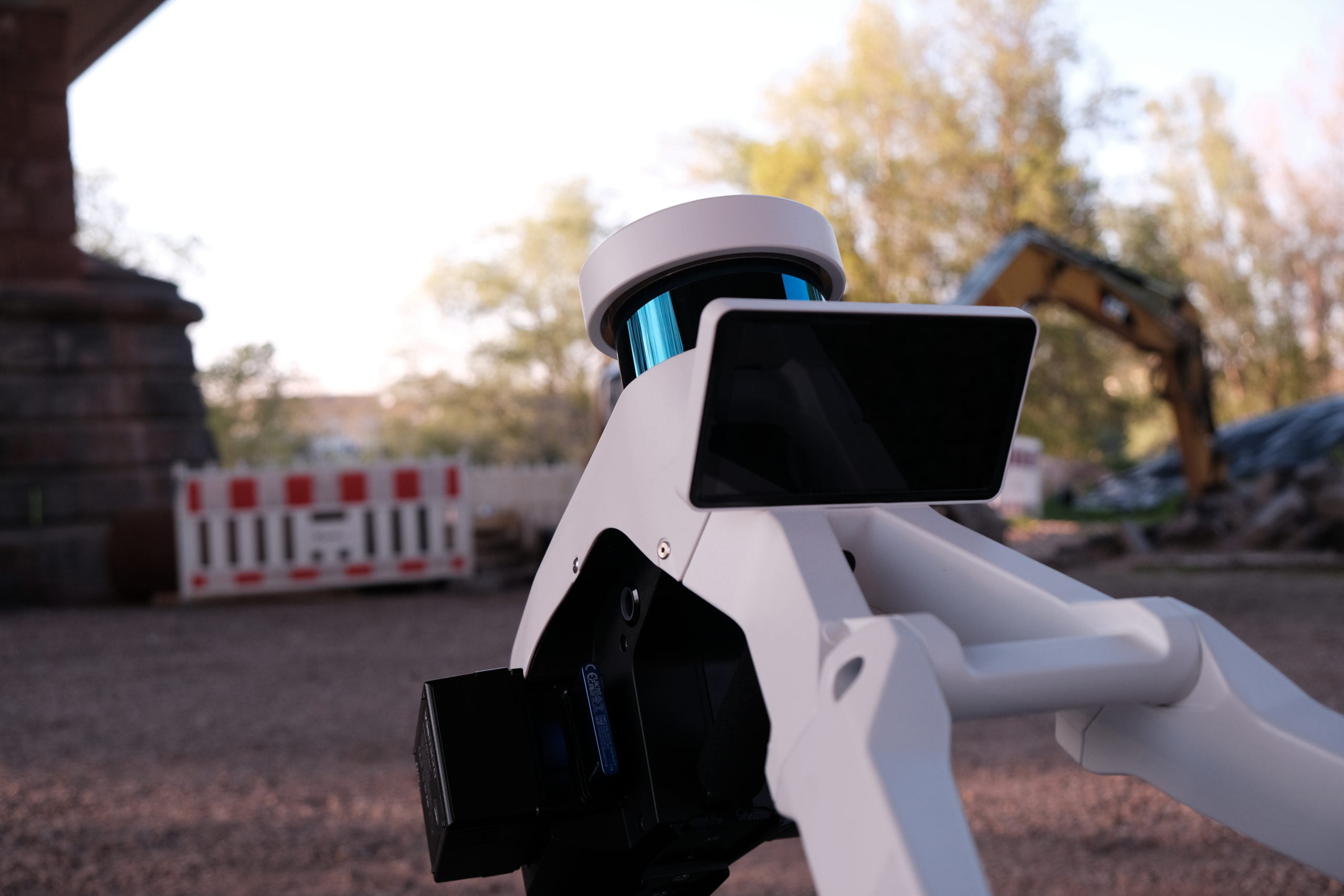

Use of 3D Laser Scanning

To ensure precise and efficient planning of the modernization measures, Knauf opted to use 3D laser scanning. This technology allows existing structures to be captured quickly and in great detail without interrupting ongoing operations. By generating point clouds, accurate 3D models of the plants were created, serving as a foundation for planning.

Advantages of 3D Laser Scanning in This Project

- Minimal Operational Disruption: The scanning of the plants could be carried out during ongoing operations, avoiding downtime.

- High Precision: The generated 3D models enabled millimeter-accurate planning of the modernization measures, improving the quality and efficiency of the upgrades.

- Efficient Planning: The detailed models allowed potential issues to be identified and resolved early, leading to smoother implementation.

- Cost Savings: Precise planning reduced unforeseen expenses and helped ensure the project stayed within budget.

Limitation: No Publication of Images Due to Data Protection Regulations

Unfortunately, we are unable to publish images of the modernized plants due to data protection regulations. Protecting privacy and complying with the General Data Protection Regulation (GDPR) are our top priorities. According to the GDPR, the explicit consent of individuals is required to publish photos in which they are identifiable. Since employees are often visible in industrial environments, appropriate precautions must be taken to safeguard personal rights.

Result: Successful Modernization with Cutting-Edge Technology

By using 3D laser scanning, Knauf was able to modernize its plants efficiently without significantly disrupting production flow. This project highlights the importance of modern surveying technologies for the successful implementation of industrial modernization efforts.

The use of 3D laser scanning in the modernization of Knauf’s plants impressively demonstrates how innovative technologies can help overcome industrial challenges and enhance process efficiency.

97297 Waldbüttelbrunn

wuerzburg@metrika360.de

95512 Neudrossenfeld

bayreuth@metrika360.de

80637 München

muenchen@metrika360.de

44149 Dortmund

dortmund@metrika360.de