Case Study Max Bögl

Der Case

As-Built Analysis and Modeling Based on a Point Cloud

It is clear to most people involved in this exciting field that the working method BIM (Building Information Modeling) is the future of planning and construction. Sometimes it is difficult to summarize this methodology in simple and concise terms. The reason for this is that the topic spans multiple disciplines within the construction industry and offers a wide range of sustainable planning and construction documentation.

In the spring of this year, one of the largest German general contractors, Max Bögl, contacted us regarding an exciting project where we had the opportunity to apply our BIM expertise in a practical setting. The following text explains in more detail the possibilities enabled by the BIM method.

The Task

We were assigned the following task:

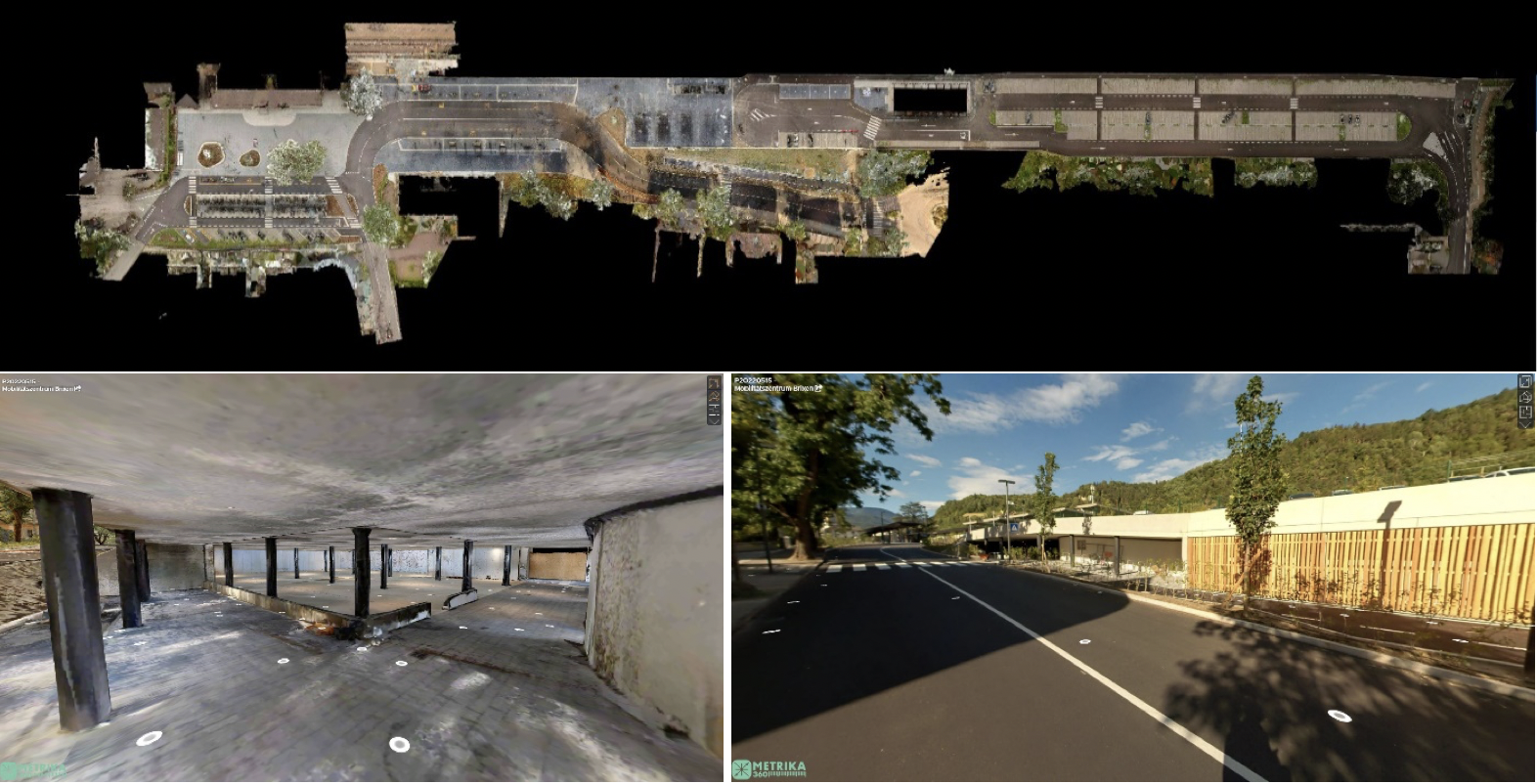

The STA – South Tyrolean Transport Structures AG commissioned the consortium Klapfer Bau, Goller Bögl, Wipptaler Bau, and Marx with the construction of a mobility center at the train station in Brixen, South Tyrol. In this BIM pilot project, Goller Bögl / Max Bögl took over the BIM coordination on behalf of the consortium. The station square is intended to serve as a “modern mobility hub” for the town. On approximately 20.000 m², about 200 car parking spaces, around 1,000 bicycle parking spaces, bus turning areas, and an adjoining train station were created.

The original execution planning was based on a highly detailed BIM model, which consisted of several sub-models from various trades.

The client required that site-specific changes and geometric deviations between the execution planning and the actual constructed state be documented and incorporated into the execution models. The updated new construction inventory thus serves as the basis for the client during the operation phase of the building. Additionally, the responsible site managers wanted an updated model available. In short: an “As-Built” model had to be created to provide a basis for billing. This workflow was intended to spare the site managers from tedious paper evaluations based on manually recorded measurements or billing sheets.

The Workflow

To meet the requirements of this assignment, the following workflow was chosen:

Measurement using Laser Scanner (Mobile Mapping)

First, a survey of the entire facility was to be carried out after the completion of construction activities. Surveys of this scope are performed by us using the mobile laser scanner VLX from NavVis. For quality control and georeferencing of the point cloud, both the existing fixed reference points on the construction site and additional surveyed control points were used.

This laser scanner enables us to capture the entire facility as a raw point cloud within a relatively short time frame while maintaining the agreed measurement tolerances on site. A special challenge was also capturing the data during ongoing operations. The field team required approximately one working day for measuring the control points and capturing data with the mobile laser scanner.

To enable simultaneous use of the processed data as a “viewer,” it was decided to create a virtual tour using the Benaco Viewer. High-resolution camera data is aligned with the point cloud data while simultaneously integrating the panoramas from the laser scanner. This results in a fully virtual, walkable, and comprehensible tour of the new facility alongside the point cloud.

The Analysis

After all laser scan data had been processed and registered, we had a very solid foundation to begin the main part of the task.

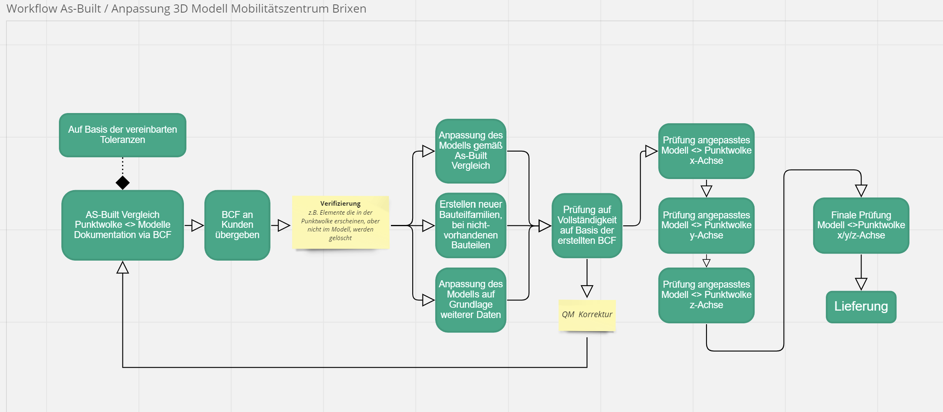

First, it had to be determined to what extent the planning matched the actual execution. For this purpose, the georeferenced point cloud was directly overlaid with the georeferenced model. Together with the client, tolerances were defined in advance to filter out negligible deviations. The diagram below illustrates the entire workflow of the As-Built process, which we agreed upon.

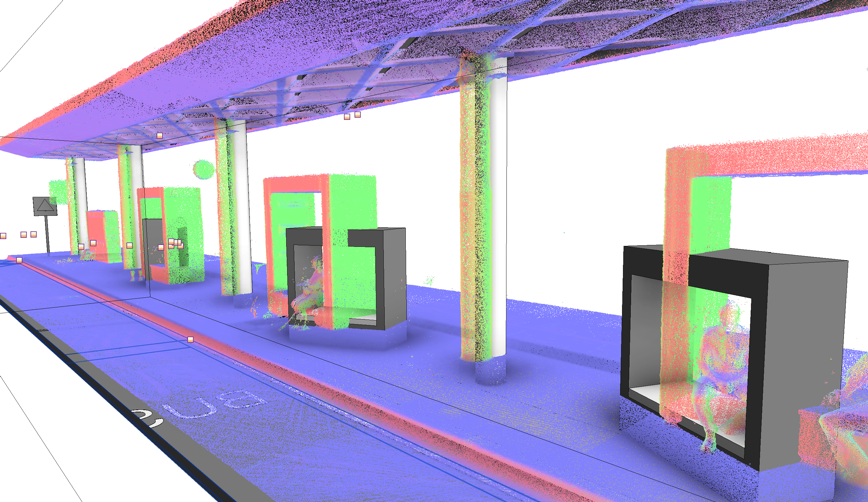

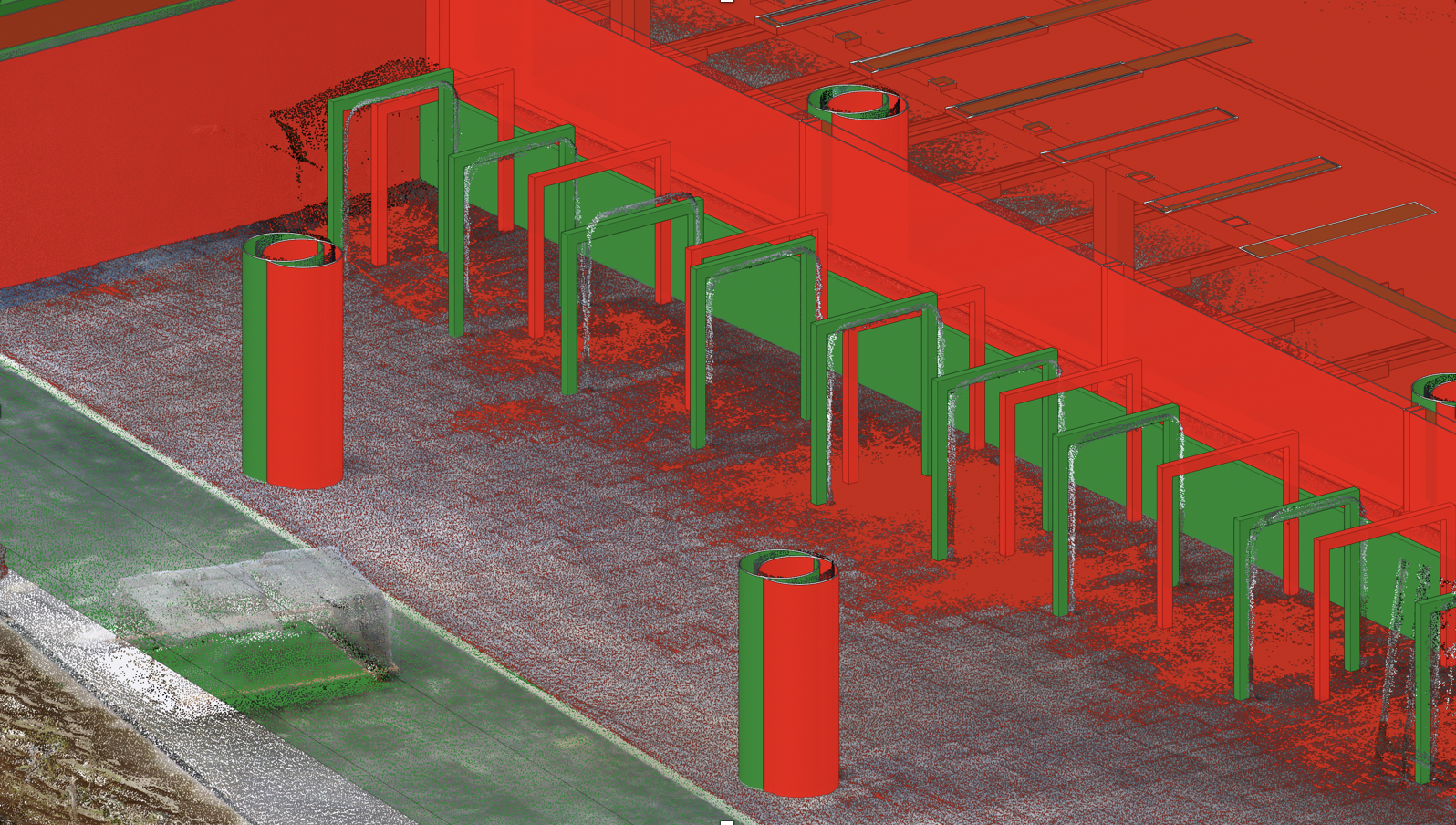

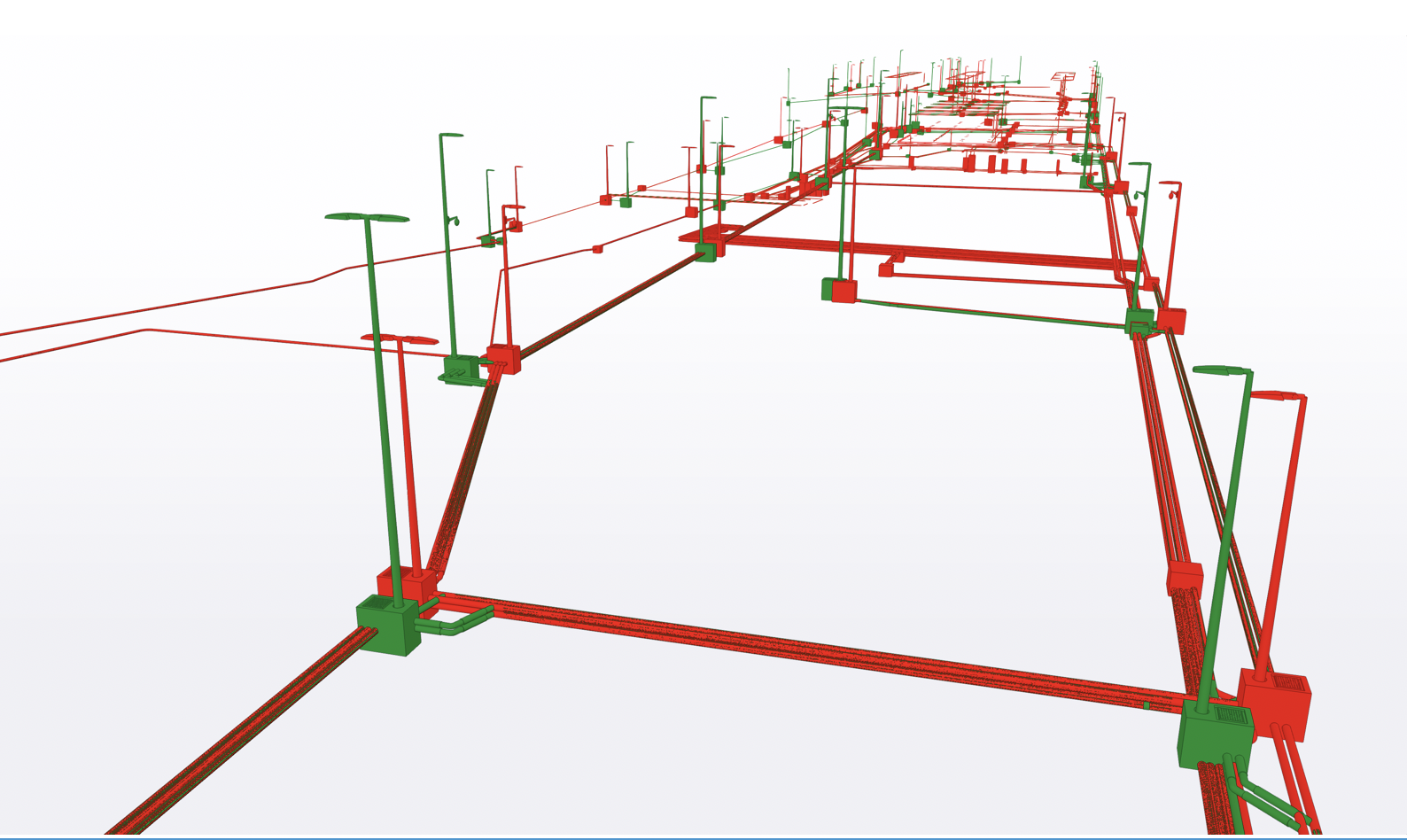

The following illustration shows the generated point cloud with the overlaid planning model.

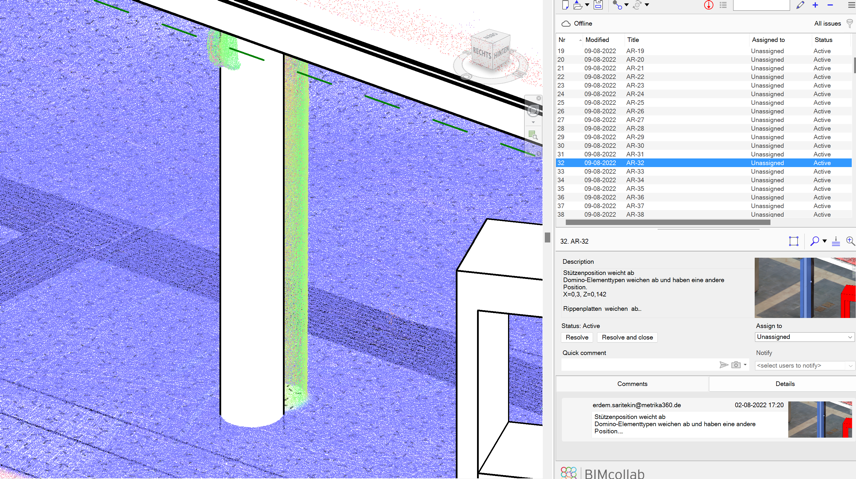

Based on this and a systematic approach, the differences between the planning and the actual execution could be easily documented. As an interface for documentation, a so-called “BCF“-file was created using the REVIT plugin “BIM Collab Manager.” In this file, deviations outside the defined tolerances can be documented on a component-specific basis, giving the client the opportunity to systematically review and evaluate individual viewpoints and recorded discrepancies.

Using the BCF file we provided, our client was able to import the deviation analysis into their local Revit model and clearly list all elements that were outside the tolerance limits.

As-Built Modeling Based on the BCF Documentation

After analyzing the individual trades and compiling an extensive BCF documentation, it was determined which deviations should actually be incorporated into the models. Here, the BCF documentation was again used as a reference to adjust the list of building components.

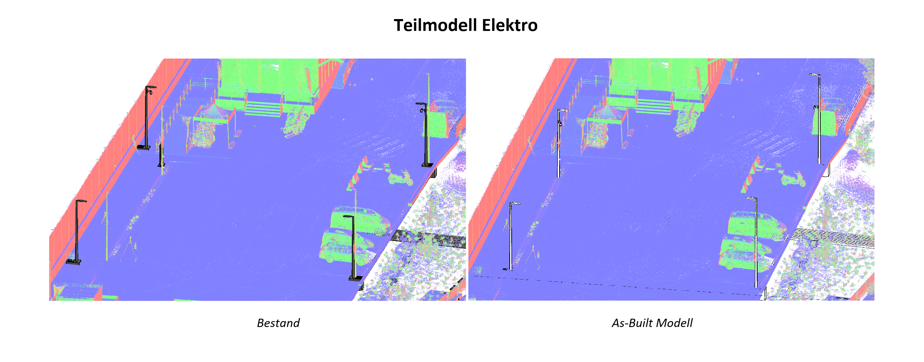

Of course, as with every construction project, there were components that had already been sealed. These included, for example, underground cables for power poles. Since these cannot realistically be reconstructed afterwards without additional aids, it was decided to shift the cables logically according to the relocated positions of the power poles. Although this does not provide a 100% guarantee of the actual execution, the model offers a simple method to check the plausibility of the installed cables.

The model serves as a basis for communication and as a data source before, during, and after the construction of a building. Even though this represents only one part of the BIM method and there are many other use cases, this practical example clearly demonstrates the great potential in sustainable modeling of buildings.

Partial electrical model in comparison of as-built condition to as-built model (Metrika360-Kling&Schrievers Ingenieure AG)

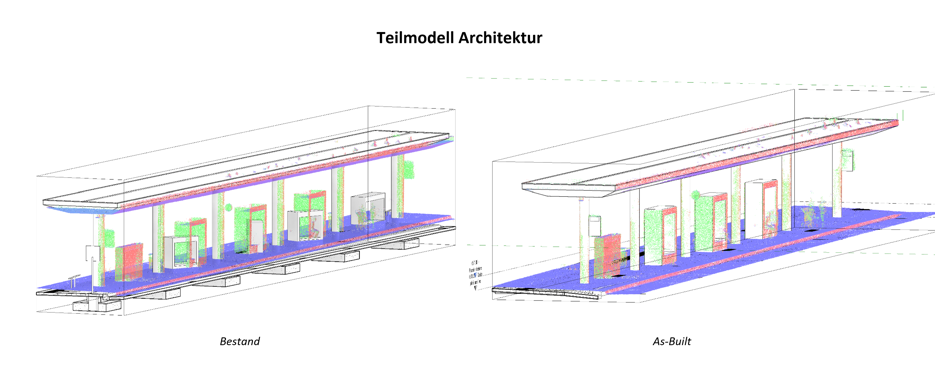

Partial architectural model in comparison of as-built condition to as-built model (Metrika360-Kling&Schrievers Ingenieure AG)

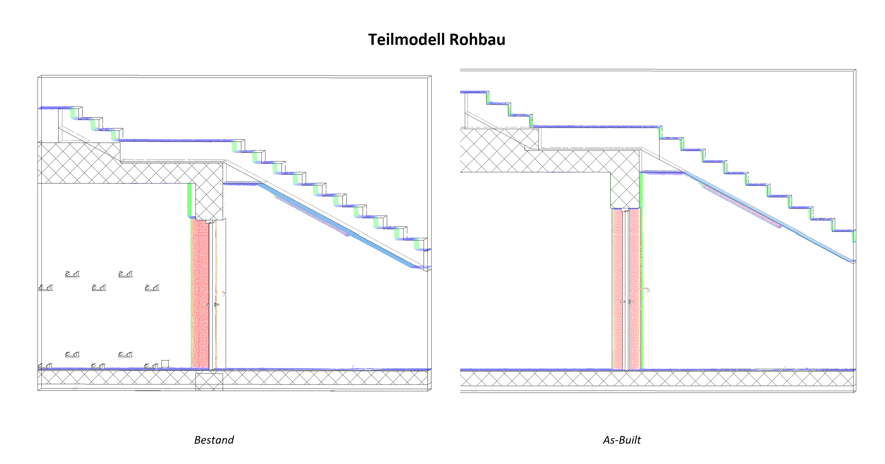

Partial structural shell model in comparison of as-built condition to as-built model (Metrika360-Kling&Schrievers Ingenieure AG)

Partial structural shell model in comparison of as-built condition to as-built model (Metrika360-Kling&Schrievers Ingenieure AG)

Section of partial electrical model – planning (red) and as-built (green) overlaid with point cloud (Goller Bögl / Max Bögl)

Section of partial architectural model – planning (red) and as-built (green) overlaid with point cloud (Goller Bögl / Max Bög!)

Section of partial structural shell model – planning (red) and as-built (green) overlaid with point cloud (Goller Bögl / Max Bögl)

Section of partial electrical model – planning (red) and as-built (green) (Goller Bögl / Max

Bögl)